2175301 wrote:Overall you are correct it's a small piece of the puzzel. But, it could be strtegically an important piece as it would buy Boeing in the range of 5 years of market advantage - even if its only a $ Million per aircraft as Airbus would have to go through a similar learning curve in order to catch up.

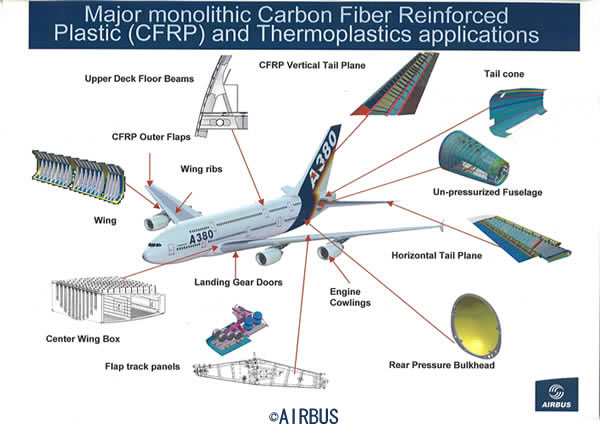

If what we are calling the 797 is indeed introduced as CFRP barrel construction - you can bet that Boeing has figured something out that cannot likely be matched by panel on frame for production cost. If it's panels on frame, then they have not.

I'm just open to that possibility - and even see it as a potential realisitic possibility. It would make that part of the the investment into the 787 pay off hugely...

To be fair, I have no issue with keeping an open mind - it's clearly possible that there has been an improvement beyond learning curve in the barrel construction. But here's my issue.

The 787 has been produced since 2004 and delivered since 2011. By the launch of the A330NEO in 2014 they had delivered some 200 frames and were at 100 per year rate. Yet between the 2014 launch of the A330NEO and its October 2017 first flight, Airbus managed to sell 440 A330's of all types against 272 x 787's. (per wikipedia)

https://en.wikipedia.org/wiki/Airbus_A330neo#OrdersBoeing could not leverage enough to smother the A330/NEO prior to 2018. However, in 2018 we see Boeing being way more aggressive with the 787

What has changed since 2017?..

1. The 787 has experienced a

planned increase in its production rate up to 14 per month, improving both availability and cost.

2. Boeing have embarked on an intensive application of ALM to reduce the cost of titanium components by what they hope will be up to $3M per frame

3. Boeing are

perceived to be undertaking an unprecedented approach to squeezing supply chain costs on the 787

4. the A330 NEO IS has been delayed by some 12 months, and this has made A330NEO contracts vulnerable to re-negotiation.

You look at all those factors I've listed, and then tell me it's more likely that Boeing have suddenly discovered some magic in the CFRP barrels at LN 700+ that makes them able to out-bid Airbus on the A330NEO in 2018 that they couldn't previously.

My apologies, but respectfully, Occam's razor is sharp for a very good reason.

IMO reasons 1 and 4 above - the considerable rate increase, and the vulnerability of the A330NEO contractually are the two biggest reasons we have seen Boeing getting very aggressive with price on the 787 in 2018.

Reasons 2 and 3 will be strong contributors to that process.

The thing with reasons 2 and 3 though is that they constitute normal business IMO for any worthy manufacturer.

Why is this important on this thread?

Because if we look at how the 787 factors read across into MOM vs an Airbus response based on the A320 we might see a slightly different picture emerging.

1. Production rate. I don't envy anyone going up against the A320 family (or 737) today in terms of cost when these frames are likely to passing 60 per month and upwards - the economies of scale are simply staggering

2. ALM - much has been made of Boeing's approach to ALM on the 787 - rightly so. Unfortunately most of us seem to have interpreted it as Boeing taking a lead of some sorts when it isn't. Something different is going on IMO, and it is a very, very important dynamic, in my view.

The best way to leverage advantage is to play to your strength. Boeing are clearly doing so with implementing ALM on the 787. They make great play of it.

You don't hear anything much at all about the implementation of ALM on the 737. I bet there is some, and I predict there will be more. But it seems that Boeing are focussing on the 787 as the priority.

What most people seem to have missed is that Airbus have gone to huge efforts to implement ALM on the A320 series in a big way. I don't know why its missed, because there is a fair amount of information out there about it. They are well down the track of replacing a large part of the TI components for cost, and have already turned some attention to the replacement of "lesser" parts for performance purposes. The obvious example of which is the "bionic bulkhead" which is the

standard cabin partition, but ALM reduces it from 75kg to 30kg. 4 of these partitions on an A321 reduces its weight by 180kg. They are not expensive items.

We hear some things on the A350, but not to the same extent. So why have Airbus focussed on the A320 first? Because it plays to their strength, of course.

Despite the intense competiton from the 737, and the huge ramp-up issues the NEO has, it is hard to avoid concluding that Airbus must be making some 14%-15% margin on the A320 series. Indeed in Q4 last year when they managed to get some of the many gliders to fly, this must have been nearer 16%-18%.

The Q4 2017 Airbus Commercial margin of c.11% didn't come from any of the other programmes - A380, A350, A330, did it?

It is my belief that if Pratt pull their finger out in 2018 the A320 will be approaching 20% margin by the end of the year.

And a thought for you. we have seen Boeing use the "dumping" argument in the USA, and I remain convinced that the threat of a dumping claim has been fundamental in the loss of the HA and AA A330NEO prospects, when Boeing are free to price so aggressively.

Yet Airbus can place big A320NEO contracts with impunity with US based customers. Because Boeing cannot exert enough pricing on so many frames to invoke a dumping claim when the A320 production costs are so low.

As for the other factors

3. Aggressive supply chain management. For every increase in the aggression shown by Boeing, I expect a like response from Airbus. This is not a sustainable competitive advantage. It has been posted on this forum that evidence of this has been observed by members from Airbus, but I can only assume it got lost in the 787 hype.

4. Contract delays. This is the only place I think the A320 is vulnerable, and indeed we saw QR order the MAX verbally citing issues with the NEO as a cause. I suspect that by the time MOM gets moving, these issues will be behind the A320.

I know that was a long response. I apologise.

But it outlines my reasons why I don't think MOM being produced with CFRP barrels will make much difference to its competitiveness with an A320 Plus, or plus-plus, provided Airbus can keep enough commoniality with the base A320 series to leverage economies of scale.

Revelation wrote:The point I was trying to make was that 797 will learn a lot from 787 and it will be a much smaller development effort than 787 itself was. In retrospect I should not have used the A350 example the way I did. Instead, I should have said 797 will learn a lot from 787 just like A350 learned a lot from A380. But the main point still stands: I don't think 797 will be as big an effort as 787 turned out to be, for many different reasons.

I must agree completely. I think Boeing did most of the technology heavy lifting on the 787. I don't think they can afford to, or will be prepared to, make the MOM another moonshot. Anything they do will be incremental at best from the 787.

Rgds