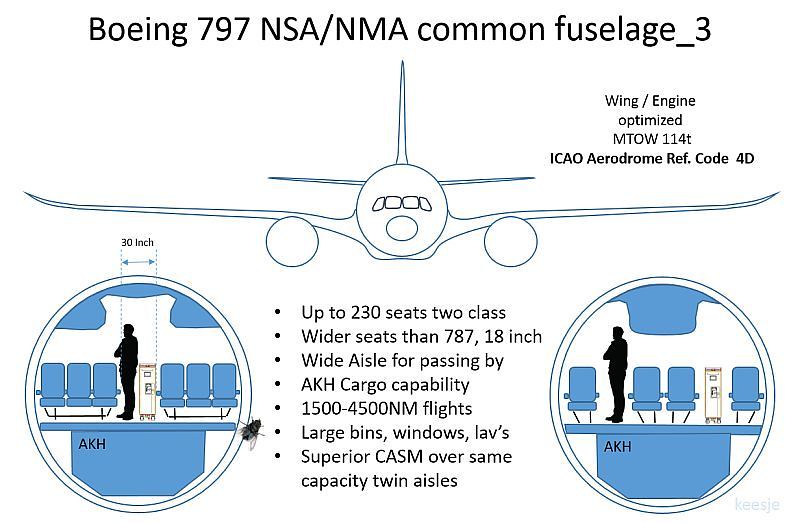

Newbiepilot wrote:This picture is why I think the A320neo Supply chain is more complex than the 737

The supply chain, for any aircraft including A320 or 737, is a long chain of tiered suppliers providing structural components as well as a myriad of pipes, ducts, brackets, avionics components, pumps, valves, fans, harnesses etc...All managed in configuration, tested and qualified, and shipped from all over the world. That is where the complexity lies.

This is just the tail end, and its focus on structural parts misses that fact that these sections are actually pre-equipped modules which will come together at the FAL...just like the 787 !

So what the diagram actually means is that instead of hundreds of thousands of parts converging onto a single FAL location, the supply chain is effectively split into several sub-chains with little overlap. This would actually tend to simplify management of operational variabilities, and avoids creating a mega logistics chocking point at the FAL

It seems that subsequent posts are on this theme as well : systems installation is likely equivalent to structural assembly in terms of driving lead times, man-hours, specialist tooling and critical paths. In some cases it may have become the only driver. I would suspect that procurement costs are still driven by the massive structures made of expensive materials, but the costs of qualified system components are probably not that far behind.

So going forward, "streamlining production processes" is most likely a heavy work on system design and installation within the structure, rather than pure structural design considerations.

Which is why I join Astuteman in saying that this discussion about barrels vs panels is fairly meaningless. And it cannot be considered only from a structural point of view, as systems considerations may be important drivers as well (high power/high voltage electrics, fiber optics directly integrated into the structure, combined structure/system modules...)