Moderators: richierich, ua900, PanAm_DC10, hOMSaR

-

- fightforlove

- Posts: 138

- Joined:

Re: Boeing 797 Discussion Thread - 2018

The purpose of the 797-6X is clear, but what missions would the larger 7X proposed variant be pitched at?

Re: Boeing 797 Discussion Thread - 2018

Revelation wrote:Seems Boeing's sales guy is emphasizing that a CFRP fuse is still getting very strong consideration.“We are committed to continuing looking at a composite structure,” said Boeing sales chief Ihssane Mounir.

“The production system continues to benefit from the composite technology and what we learned from the 787,” Mounir said. “The composite structure remains a major, major consideration.”

He declined to say anything more definitive.

Ref: https://www.seattletimes.com/business/b ... not-metal/

Yet not a definitive "we will do CFRP" statement either.

It seems the numbers must be pretty compelling for metal, because it probably is easier to sell CFRP as being a more modern and more durable ( long term ) material.

Yes, CFRP fuselages have issues with ramp rash, but they also doesn't corrode like metal does and thus avoids a lot of costly inspections and repairs.

It must be an interesting lifecycle computation.

Some articles suggest that airliners life span is now limited more by the avionics than the structures.

That would suggest that one should either design the avionics and related wiring conduits to be easy(-ish) to upgrade, or one should accept the shorter life span and do whatever makes the plane cheaper to manufacture, and presumably this means metal structures for the fuse.

And then there's the strategic decision: if Boeing is now demanding a slice of the after market profits and are building more things in house rather than using vendors, does it make more money for them if the structures are somewhat more costly up front but age more gracefully?

Metal and CFRP is a wash. Metal has corrosion, CFRP has delamination, so unless you need the high tensile strength of CFRP the materials are quite similar in performance. What will be difficult with CFRP is a P2F conversion, because either you prepare the structure for a door right from the start or you can practically forget it. So each frame would be carrying excess weight just to be ready for a cargo conversion.

Re: Boeing 797 Discussion Thread - 2018

fightforlove wrote:The purpose of the 797-6X is clear, but what missions would the larger 7X proposed variant be pitched at?

"Kontschaufel" missions all over the world. Stuff under ~3200 nm that is being flown today by A321s or 757s. Imagine having 15% higher trip cost than an A321neo but 25% more seats.

Re: Boeing 797 Discussion Thread - 2018

seabosdca wrote:fightforlove wrote:The purpose of the 797-6X is clear, but what missions would the larger 7X proposed variant be pitched at?

"Kontschaufel" missions all over the world. Stuff under ~3200 nm that is being flown today by A321s or 757s. Imagine having 15% higher trip cost than an A321neo but 25% more seats.

Or to put it simply, a [relatively] short range air bus (wait a minute...)

Re: Boeing 797 Discussion Thread - 2018

seahawk wrote:Revelation wrote:Seems Boeing's sales guy is emphasizing that a CFRP fuse is still getting very strong consideration.“We are committed to continuing looking at a composite structure,” said Boeing sales chief Ihssane Mounir.

“The production system continues to benefit from the composite technology and what we learned from the 787,” Mounir said. “The composite structure remains a major, major consideration.”

He declined to say anything more definitive.

Ref: https://www.seattletimes.com/business/b ... not-metal/

Yet not a definitive "we will do CFRP" statement either.

It seems the numbers must be pretty compelling for metal, because it probably is easier to sell CFRP as being a more modern and more durable ( long term ) material.

Yes, CFRP fuselages have issues with ramp rash, but they also doesn't corrode like metal does and thus avoids a lot of costly inspections and repairs.

It must be an interesting lifecycle computation.

Some articles suggest that airliners life span is now limited more by the avionics than the structures.

That would suggest that one should either design the avionics and related wiring conduits to be easy(-ish) to upgrade, or one should accept the shorter life span and do whatever makes the plane cheaper to manufacture, and presumably this means metal structures for the fuse.

And then there's the strategic decision: if Boeing is now demanding a slice of the after market profits and are building more things in house rather than using vendors, does it make more money for them if the structures are somewhat more costly up front but age more gracefully?

Metal and CFRP is a wash. Metal has corrosion, CFRP has delamination, so unless you need the high tensile strength of CFRP the materials are quite similar in performance. What will be difficult with CFRP is a P2F conversion, because either you prepare the structure for a door right from the start or you can practically forget it. So each frame would be carrying excess weight just to be ready for a cargo conversion.

Agree on no cargo conversions if you do metal. However I can’t imagine even if the fuselage is metal on the outside that you won’t end up with CFRP or other non optimal pieces throughout the structure for a P2F program. We have seen the obstacles that poses for the 777 after all. Weight is still going to be a concern so the passenger variant, even if it is skinned with metal, is likely to use as light of material as possible throughout.

In theory if you want to use barrels you could simply do a unique forward fuselage section for the freighter version. The 787 is built in four fuselage sections, nose, forward, center and rear, so you could take the forward fuselage section and build one unique with a door if you really wanted.

Agree a conversion is almost impossible short of detaching the nose from the center fuselage and replacing it. I have no idea how hard or easy it would be to detach those fasteners and then put the thing back together. Absent that you won’t be converting anything.

I think one of the biggest factors will be MX issues and regulatory acceptance of certain types of fixes. Less of an issue for big planes it’s a big issue on this program depending on how low down the chain you want to utilize the fuselage. There is certainly an upfront cost control element in the decision as well but from what little I have heard MX considerations play a huge role in this.

Re: Boeing 797 Discussion Thread - 2018

seahawk wrote:

Metal and CFRP is a wash. Metal has corrosion, CFRP has delamination, so unless you need the high tensile strength of CFRP the materials are quite similar in performance. What will be difficult with CFRP is a P2F conversion, because either you prepare the structure for a door right from the start or you can practically forget it. So each frame would be carrying excess weight just to be ready for a cargo conversion.

I agree with the first half of your statement and will add that when it comes to maintainability and repairs that it can be a wash there as well. What is worse is your pilot isn't going to detect delaminations etc on a walk around. Fortunately composite allowables are so conservative that it's fine. (This is where we've learned a lot from 787 and how overdesigned it is)

I don't agree with your second statement. A composite fuselage is just as easy to retrofit as a metallic fuselage. Unfortunately for mod shops out there they won't be able to do this type of work though. Not without OEM data (which Boeing won't give you I can guarantee that). You can't reverse engineer the sizing that Boeing did under an STC mod for a P2F conversion like you can with a metal fuselage. Metal allowables are well documented (MMPDS for instance) but Boeing isn't going to give you their allowables for CFRP. The best you could probably do is when you cut out cargo door in the fuselage is take that material and go do some coupon testing to develop some allowables of your own and applying that to your sizing. Good luck getting the FAA to buy off on that in your STC.

Of course none of that really matters since Boeing does their own P2F conversions and will probably offer a 797 freighter option anyways.

Re: Boeing 797 Discussion Thread - 2018

seahawk wrote:Revelation wrote:Seems Boeing's sales guy is emphasizing that a CFRP fuse is still getting very strong consideration.“We are committed to continuing looking at a composite structure,” said Boeing sales chief Ihssane Mounir.

“The production system continues to benefit from the composite technology and what we learned from the 787,” Mounir said. “The composite structure remains a major, major consideration.”

He declined to say anything more definitive.

Ref: https://www.seattletimes.com/business/b ... not-metal/

Yet not a definitive "we will do CFRP" statement either.

It seems the numbers must be pretty compelling for metal, because it probably is easier to sell CFRP as being a more modern and more durable ( long term ) material.

Yes, CFRP fuselages have issues with ramp rash, but they also doesn't corrode like metal does and thus avoids a lot of costly inspections and repairs.

It must be an interesting lifecycle computation.

Some articles suggest that airliners life span is now limited more by the avionics than the structures.

That would suggest that one should either design the avionics and related wiring conduits to be easy(-ish) to upgrade, or one should accept the shorter life span and do whatever makes the plane cheaper to manufacture, and presumably this means metal structures for the fuse.

And then there's the strategic decision: if Boeing is now demanding a slice of the after market profits and are building more things in house rather than using vendors, does it make more money for them if the structures are somewhat more costly up front but age more gracefully?

Metal and CFRP is a wash. Metal has corrosion, CFRP has delamination, so unless you need the high tensile strength of CFRP the materials are quite similar in performance. What will be difficult with CFRP is a P2F conversion, because either you prepare the structure for a door right from the start or you can practically forget it. So each frame would be carrying excess weight just to be ready for a cargo conversion.

P2F with composites may be more difficult or require a new approach but it is not like needing to prepare the structure for a door/dense cargo is unique to composites. You have to do the same with metal. Boeing and Airbus are not designing their metal pax planes to be prepared for a large door on the side from the factory, conversion requires a lot of extra structure and reinforcement which is why P2Fs always perform worse than their factory fresh freighter counterparts. Just look at a picture of the A333P2F after it was converted but before it was repainted and see how much extra reinforcement was adding all along the plane.

Re: Boeing 797 Discussion Thread - 2018

Polot wrote:P2F with composites may be more difficult or require a new approach but it is not like needing to prepare the structure for a door/dense cargo is unique to composites. You have to do the same with metal. Boeing and Airbus are not designing their metal pax planes to be prepared for a large door on the side from the factory, conversion requires a lot of extra structure and reinforcement which is why P2Fs always perform worse than their factory fresh freighter counterparts. Just look at a picture of the A333P2F after it was converted but before it was repainted and see how much extra reinforcement was adding all along the plane.

Quite right. As I noted the main issue is not knowing the capability of the composites that are there. In theory you can back out the sizing using Pr/t for hoop and Pr/2t for longitudinal but it's not that simple with composites really. Metal its easy work for a stress engineer. If you don't know the stackup of the composite or the allowables it just becomes a big bit of guess work. Hence doing coupon testing with anything you cut out.

At any rate, it won't matter because Boeing will have a hold on that market as their global services team will handle any P2F conversions and seattle/charleston will handle the clean sheet design.

Re: Boeing 797 Discussion Thread - 2018

trpmb6 wrote:seahawk wrote:

Metal and CFRP is a wash. Metal has corrosion, CFRP has delamination, so unless you need the high tensile strength of CFRP the materials are quite similar in performance. What will be difficult with CFRP is a P2F conversion, because either you prepare the structure for a door right from the start or you can practically forget it. So each frame would be carrying excess weight just to be ready for a cargo conversion.

I agree with the first half of your statement and will add that when it comes to maintainability and repairs that it can be a wash there as well. What is worse is your pilot isn't going to detect delaminations etc on a walk around. Fortunately composite allowables are so conservative that it's fine. (This is where we've learned a lot from 787 and how overdesigned it is)

I don't agree with your second statement. A composite fuselage is just as easy to retrofit as a metallic fuselage. Unfortunately for mod shops out there they won't be able to do this type of work though. Not without OEM data (which Boeing won't give you I can guarantee that). You can't reverse engineer the sizing that Boeing did under an STC mod for a P2F conversion like you can with a metal fuselage. Metal allowables are well documented (MMPDS for instance) but Boeing isn't going to give you their allowables for CFRP. The best you could probably do is when you cut out cargo door in the fuselage is take that material and go do some coupon testing to develop some allowables of your own and applying that to your sizing. Good luck getting the FAA to buy off on that in your STC.

Of course none of that really matters since Boeing does their own P2F conversions and will probably offer a 797 freighter option anyways.

There I disagree because with a metal fuselage I can change the load bearing structure as required. I can add new stringers, strengthen parts and so on. If I cut a big hole in the CFRP barrel I destroy the load bearing characteristics of the structure but I can not easily fix this by replacing parts. You would need to attach an additiona lstructure to the remaining barrel that takes the changed loads and distributed it to the remaining strucutre, but this requires the CFRP structure to be prepared for that.

Re: Boeing 797 Discussion Thread - 2018

seahawk wrote:

There I disagree because with a metal fuselage I can change the load bearing structure as required. I can add new stringers, strengthen parts and so on. If I cut a big hole in the CFRP barrel I destroy the load bearing characteristics of the structure but I can not easily fix this by replacing parts. You would need to attach an additional structure to the remaining barrel that takes the changed loads and distributed it to the remaining strucutre, but this requires the CFRP structure to be prepared for that.

Does it? I think not. There are many ways to handle it. Nothing says you can't bolt metallic structure to CFRP structure. You just have to account for induced thermal loading and any corrosion issues due to dissimilar materials. You could also do secondary bonds with new composite structure if you have a way of inspecting your bond lines. FAA is touchy on that.

Trust me it's not that big of a deal. The main issue is not knowing the allowables Boeing used.

Re: Boeing 797 Discussion Thread - 2018

trpmb6 wrote:seahawk wrote:

There I disagree because with a metal fuselage I can change the load bearing structure as required. I can add new stringers, strengthen parts and so on. If I cut a big hole in the CFRP barrel I destroy the load bearing characteristics of the structure but I can not easily fix this by replacing parts. You would need to attach an additional structure to the remaining barrel that takes the changed loads and distributed it to the remaining strucutre, but this requires the CFRP structure to be prepared for that.

Does it? I think not. There are many ways to handle it. Nothing says you can't bolt metallic structure to CFRP structure. You just have to account for induced thermal loading and any corrosion issues due to dissimilar materials. You could also do secondary bonds with new composite structure if you have a way of inspecting your bond lines. FAA is touchy on that.

Trust me it's not that big of a deal. The main issue is not knowing the allowables Boeing used.

I don't know much about CFRP, but I have worked with fiberglass...and bonding/fastening extra structure to it, not only isn't a big deal, if it's a 'shaped' structure, it's easier to do than on a metal structure. While the materials are different, I would be very surprised if the principles aren't the same.

I imagine it would be similar to making a repair...but using more material.

Re: Boeing 797 Discussion Thread - 2018

JoeCanuck wrote:trpmb6 wrote:seahawk wrote:

There I disagree because with a metal fuselage I can change the load bearing structure as required. I can add new stringers, strengthen parts and so on. If I cut a big hole in the CFRP barrel I destroy the load bearing characteristics of the structure but I can not easily fix this by replacing parts. You would need to attach an additional structure to the remaining barrel that takes the changed loads and distributed it to the remaining strucutre, but this requires the CFRP structure to be prepared for that.

Does it? I think not. There are many ways to handle it. Nothing says you can't bolt metallic structure to CFRP structure. You just have to account for induced thermal loading and any corrosion issues due to dissimilar materials. You could also do secondary bonds with new composite structure if you have a way of inspecting your bond lines. FAA is touchy on that.

Trust me it's not that big of a deal. The main issue is not knowing the allowables Boeing used.

I don't know much about CFRP, but I have worked with fiberglass...and bonding/fastening extra structure to it, not only isn't a big deal, if it's a 'shaped' structure, it's easier to do than on a metal structure. While the materials are different, I would be very surprised if the principles aren't the same.

I imagine it would be similar to making a repair...but using more material.

Yes, if it was a huge deal than any hole or damage to composite aircraft would be the death knell to the plane. It obviously isn’t, ET’s 787 fire is plenty proof of that. The major new issue is inexperience on a composite P2F, but that can be overcome.

Re: Boeing 797 Discussion Thread - 2018

Just remember, don't put aluminum and CFRP in contact with each other. It'll corrode faster than metal under a lav.

Re: Boeing 797 Discussion Thread - 2018

trpmb6 wrote:Just remember, don't put aluminum and CFRP in contact with each other. It'll corrode faster than metal under a lav.

I believe both Airbus and Boeing use aluminum reinforcement with some of their CFRP structures.

Re: Boeing 797 Discussion Thread - 2018

JoeCanuck wrote:trpmb6 wrote:Just remember, don't put aluminum and CFRP in contact with each other. It'll corrode faster than metal under a lav.

I believe both Airbus and Boeing use aluminum reinforcement with some of their CFRP structures.

Absolutely. With proper isolation. Bare aluminum on CFRP will cause galvanic corrosion. There are ways to isolate this but I don't believe I should go any further into what the various OEM's do specifically. Each OEM has it's own preferred method (including the business jet manufacturers).

Re: Boeing 797 Discussion Thread - 2018

Maybe Boeing should focus on a circular, practical, smaller low cost fuselage that also can help them in the huge up to 220 seats / 2000NM segment effectively, before they get beaten even worse there. In general niches are for niche players.

Re: Boeing 797 Discussion Thread - 2018

Polot wrote:JoeCanuck wrote:trpmb6 wrote:

Does it? I think not. There are many ways to handle it. Nothing says you can't bolt metallic structure to CFRP structure. You just have to account for induced thermal loading and any corrosion issues due to dissimilar materials. You could also do secondary bonds with new composite structure if you have a way of inspecting your bond lines. FAA is touchy on that.

Trust me it's not that big of a deal. The main issue is not knowing the allowables Boeing used.

I don't know much about CFRP, but I have worked with fiberglass...and bonding/fastening extra structure to it, not only isn't a big deal, if it's a 'shaped' structure, it's easier to do than on a metal structure. While the materials are different, I would be very surprised if the principles aren't the same.

I imagine it would be similar to making a repair...but using more material.

Yes, if it was a huge deal than any hole or damage to composite aircraft would be the death knell to the plane. It obviously isn’t, ET’s 787 fire is plenty proof of that. The major new issue is inexperience on a composite P2F, but that can be overcome.

Just that there is a big difference between repairing a CFRP structure and modifying it for a different load distribution. Repairing means adding a replacement part and attaching it to the existing structure without any change in the load distribution. A P2F changes to the load distribution as the big cargo door alone has a huge impact on the load in the fuselage barrel as one side now has the huge hole in it. Sure you can make a replacement structures and attach it to the barrel but the attachment points must be able to take the different loads coming from the replacement structure. The closer you get to an optimal CFRP design the harder modifying it becomes.

-

- brindabella

- Posts: 775

- Joined:

Re: Boeing 797 Discussion Thread - 2018

JoeCanuck wrote:As well, all three engine makers have had huge cockups with their new engine programs...which are not all fixed yet...and Boeing will need another all new engine for the NMA. Sure...it may very well be a derivative of a current engine...but RR has shown that 'improvements' to current engines don't always work out and crappy engines cost a lot for everybody.

.

I suspect that the engine issue underlies much if not all of the delay, EG:

- - all three big engine OEMs have been up to their a**holes in alligators, and had scarce resources or attention to give to Boeing's RFP;

- some or all of the mega-airlines who are interested in becoming Launch Customers are (understandably) demanding at least 2 engine-types be available;

- however the same three large engine OEMs are also each demanding sole-source status.

Love to be a "fly on the wall"

cheers

-

- brindabella

- Posts: 775

- Joined:

Re: Boeing 797 Discussion Thread - 2018

texl1649 wrote:I wonder if Boeing is contemplating, possibly, a future line where there is one moving assembly line, with NMA, and NSA rolling down sequentially, different models/lengths, but the same basic systems getting installed (but for engines, handled later of course). Shared APU's, cockpits, etc.

Mmm, can't help but be reminded of a certain OEM which has (apparently):

- - reduced assembly-line staff from 600 or so to maybe 100;

- introduced substantial automation to the same line;

- and nevertheless builds two separate generations of it's airliners on that same line.

EMB and the E1/E2.

And of course integration of that same EMB operation with Boeing is well under way. Funny about that!

Since I haven't seen anyone else suggest this, take a bow!

And to follow this logic along, these skills at EMB would make a strong case not only for parallel assembly-lines in Sao Paulo as well as say Seattle; but also possibly the first developmental MOM/NSA (low-rate) line might be established in Brazil.

cheers

Re: Boeing 797 Discussion Thread - 2018

brindabella wrote:I suspect that the engine issue underlies much if not all of the delay, EG:- all three big engine OEMs have been up to their a**holes in alligators, and had scarce resources or attention to give to Boeing's RFP;

- some or all of the mega-airlines who are interested in becoming Launch Customers are (understandably) demanding at least 2 engine-types be available;

- however the same three large engine OEMs are also each demanding sole-source status.

Love to be a "fly on the wall"

cheers

Is the issue the design of the engines, the production methods or the actual materials used which is creating a reliability issue, depending on which those resources may not be interchangeable, so working on a new derivative engine is doable?

Politics is covering some of the issues, the GE engines are flying, the RR engines are not, however, outside of the airlines who are paying and seeing their profits disrupted, the lower performance of the GE engines must provide equivalence when discussing new products.

Re: Boeing 797 Discussion Thread - 2018

seabosdca wrote:frmrCapCadet wrote:And isn't the 878-8 likely to have a freighter version about 2025?

edit: 787-8

The freighter would need higher 787-9 weights, and therefore the beefier 787-9 gear (and, at 787-8 length, possibly a taller vertical stab). I doubt Boeing will bother to retrofit those things to the 787-8 when it could just make a 787-9F.

When Boeing got the latest order from AA for 788s, they announced that they would redesign the 788 to be like the 789. Boeing could do a simple shrink of the 789 and produce a 788ER, which would probably be a good basis for a freighter.

Re: Boeing 797 Discussion Thread - 2018

seahawk wrote:Polot wrote:JoeCanuck wrote:

I don't know much about CFRP, but I have worked with fiberglass...and bonding/fastening extra structure to it, not only isn't a big deal, if it's a 'shaped' structure, it's easier to do than on a metal structure. While the materials are different, I would be very surprised if the principles aren't the same.

I imagine it would be similar to making a repair...but using more material.

Yes, if it was a huge deal than any hole or damage to composite aircraft would be the death knell to the plane. It obviously isn’t, ET’s 787 fire is plenty proof of that. The major new issue is inexperience on a composite P2F, but that can be overcome.

Just that there is a big difference between repairing a CFRP structure and modifying it for a different load distribution. Repairing means adding a replacement part and attaching it to the existing structure without any change in the load distribution. A P2F changes to the load distribution as the big cargo door alone has a huge impact on the load in the fuselage barrel as one side now has the huge hole in it. Sure you can make a replacement structures and attach it to the barrel but the attachment points must be able to take the different loads coming from the replacement structure. The closer you get to an optimal CFRP design the harder modifying it becomes.

Boeing had their practice with the Ethiopian emergency locator fire. They can change and repair the structure of a 787 fuselage. Modifying the structure is quite possible, but adds weight. For example, a P2F door change would probably entail a new door frame fastened and glued to the opening. Not that hard, but the door frame would be 50 to 100 percent more weight than what came out.

Re: Boeing 797 Discussion Thread - 2018

The bigger issue for a P2F will be, as it is with the 777, that the lightweight floor will not support cargo containers and will have to be replaced. With a strengthened, heavier floor. Not impossible, but quite a bit of work and expense.

Re: Boeing 797 Discussion Thread - 2018

jagraham wrote:seahawk wrote:Polot wrote:Yes, if it was a huge deal than any hole or damage to composite aircraft would be the death knell to the plane. It obviously isn’t, ET’s 787 fire is plenty proof of that. The major new issue is inexperience on a composite P2F, but that can be overcome.

Just that there is a big difference between repairing a CFRP structure and modifying it for a different load distribution. Repairing means adding a replacement part and attaching it to the existing structure without any change in the load distribution. A P2F changes to the load distribution as the big cargo door alone has a huge impact on the load in the fuselage barrel as one side now has the huge hole in it. Sure you can make a replacement structures and attach it to the barrel but the attachment points must be able to take the different loads coming from the replacement structure. The closer you get to an optimal CFRP design the harder modifying it becomes.

Boeing had their practice with the Ethiopian emergency locator fire. They can change and repair the structure of a 787 fuselage. Modifying the structure is quite possible, but adds weight. For example, a P2F door change would probably entail a new door frame fastened and glued to the opening. Not that hard, but the door frame would be 50 to 100 percent more weight than what came out.

And lets not forget that the 787 was supposedly designed fromt he outset for freighter ops in mind, at least to the extent as there is nothing vital or difficult to reposition routed through the area where the SCD would be cut. Talking with FX on this would probably enable them to make choices like how easy it would be to changeover floors, final belly container sizes, etc. I could see FX taking 1 a month new, as while it's true they have some very low time/cycle 757s in their hodgepodge fleet, they also were taking anything they could get for a while and have some very elderly examples as well (like LN 15, with 90,000+ hours and 35,000+ cycles as of last year. They've reactivated the 3 stored temporarily at VCV and the fleet is only going to get older from here on out, with retirements coming as a trickle first...

Re: Boeing 797 Discussion Thread - 2018

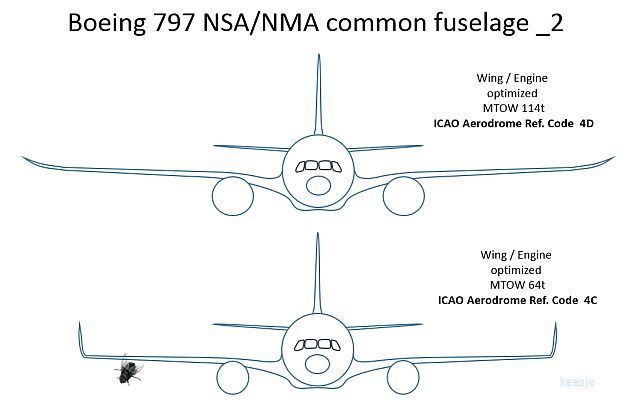

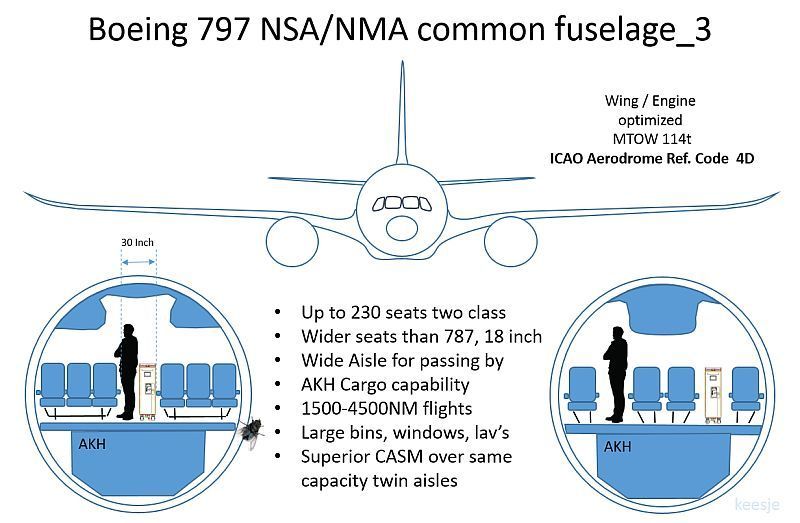

keesje wrote:Maybe Boeing should focus on a circular, practical, smaller low cost fuselage that also can help them in the huge up to 220 seats / 2000NM segment effectively, before they get beaten even worse there. In general niches are for niche players.

More single aisle MoM dreams Kessje??? If there is one thing we know about any future 797 it is that it will be a twin aisle plane.

Re: Boeing 797 Discussion Thread - 2018

In the end, the 797 will look like a reduced-size 787, a double-aisle airliner that will have a range of between 4,100 to 5,300 nautical miles and seating of 220 to 270 passengers depending on fuselage length. The engines will likely be a scaled-up version of the CFM International LEAP or a scaled-up version of the PW1100G, rated at between 36,000 to 42,000 lb of thrust.

Re: Boeing 797 Discussion Thread - 2018

jagraham wrote:keesje wrote:Maybe Boeing should focus on a circular, practical, smaller low cost fuselage that also can help them in the huge up to 220 seats / 2000NM segment effectively, before they get beaten even worse there. In general niches are for niche players.

More single aisle MoM dreams Kessje??? If there is one thing we know about any future 797 it is that it will be a twin aisle plane.

Yes, I know. Oval, composites at the cost of a NB.. but realism seems to be slowly kicking in. Low cost, low weight and addressing the A321 too. It could be a twin aisle in front, giving direct aisle access.

-

- PlanesNTrains

- Posts: 9524

- Joined:

Re: Boeing 797 Discussion Thread - 2018

keesje wrote:jagraham wrote:keesje wrote:Maybe Boeing should focus on a circular, practical, smaller low cost fuselage that also can help them in the huge up to 220 seats / 2000NM segment effectively, before they get beaten even worse there. In general niches are for niche players.

More single aisle MoM dreams Kessje??? If there is one thing we know about any future 797 it is that it will be a twin aisle plane.

Yes, I know. Oval, composites at the cost of a NB.. but realism seems to be slowly kicking in. Low cost, low weight and addressing the A321 too. It could be a twin aisle in front, giving direct aisle access.

But how would this concept fair compared to an A321XLR? Because that's what would be coming if they launch it?

It'll be interesting, if not humorous, when Boeing goes single aisle for the NMA and Airbus launches their rumored twin aisle.

Re: Boeing 797 Discussion Thread - 2018

jagraham wrote:The bigger issue for a P2F will be, as it is with the 777, that the lightweight floor will not support cargo containers and will have to be replaced. With a strengthened, heavier floor. Not impossible, but quite a bit of work and expense.

And the barrel will have to be ready for the higher loads.

Re: Boeing 797 Discussion Thread - 2018

seahawk wrote:jagraham wrote:The bigger issue for a P2F will be, as it is with the 777, that the lightweight floor will not support cargo containers and will have to be replaced. With a strengthened, heavier floor. Not impossible, but quite a bit of work and expense.

And the barrel will have to be ready for the higher loads.

That too!

Re: Boeing 797 Discussion Thread - 2018

PlanesNTrains wrote:keesje wrote:jagraham wrote:

More single aisle MoM dreams Kessje??? If there is one thing we know about any future 797 it is that it will be a twin aisle plane.

Yes, I know. Oval, composites at the cost of a NB.. but realism seems to be slowly kicking in. Low cost, low weight and addressing the A321 too. It could be a twin aisle in front, giving direct aisle access.

But how would this concept fair compared to an A321XLR? Because that's what would be coming if they launch it?

It'll be interesting, if not humorous, when Boeing goes single aisle for the NMA and Airbus launches their rumored twin aisle.

I don't a new Airbus twin aisle before 2030. Eventually the A330 needs replacement and the A321/322 - A350-900 space needs to be filled. How that will look seems unclear to me this stage. I can google an A370 single aisle on steriod, but lets not post that on the 797 thread.

-

- PlanesNTrains

- Posts: 9524

- Joined:

Re: Boeing 797 Discussion Thread - 2018

keesje wrote:PlanesNTrains wrote:keesje wrote:

Yes, I know. Oval, composites at the cost of a NB.. but realism seems to be slowly kicking in. Low cost, low weight and addressing the A321 too. It could be a twin aisle in front, giving direct aisle access.

But how would this concept fair compared to an A321XLR? Because that's what would be coming if they launch it?

It'll be interesting, if not humorous, when Boeing goes single aisle for the NMA and Airbus launches their rumored twin aisle.

I don't a new Airbus twin aisle before 2030. Eventually the A330 needs replacement and the A321/322 - A350-900 space needs to be filled. How that will look seems unclear to me this stage. I can google an A370 single aisle on steriod, but lets not post that on the 797 thread.

That’s fine, but the primary question was how would the concept you posted fair up against an A321XLR?

Re: Boeing 797 Discussion Thread - 2018

PlanesNTrains wrote:keesje wrote:PlanesNTrains wrote:

But how would this concept fair compared to an A321XLR? Because that's what would be coming if they launch it?

It'll be interesting, if not humorous, when Boeing goes single aisle for the NMA and Airbus launches their rumored twin aisle.

I don't a new Airbus twin aisle before 2030. Eventually the A330 needs replacement and the A321/322 - A350-900 space needs to be filled. How that will look seems unclear to me this stage. I can google an A370 single aisle on steriod, but lets not post that on the 797 thread.

That’s fine, but the primary question was how would the concept you posted fair up against an A321XLR?

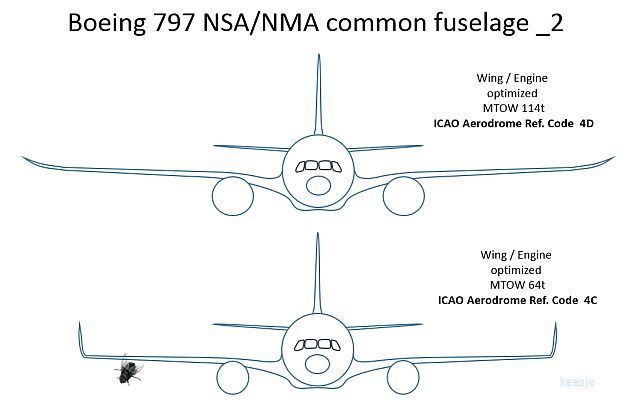

- Superior paylooad range, CASM up to 5000NM/ 280 passengers.

- Dual, direct aisle acces seats for all F/B class passengers

- Wing / engine / LDG / optimized for high capacity / short range with dedicated low MTOW version

- Quicker boarding/ deboarding with 1.5 aisle system, people can pass each other.

- Easier moving around of passengers/ crew service during flight

- Wider seats, bigger windows, bins, lavatories

High NSA/NMA commonality & economies of scale.

Re: Boeing 797 Discussion Thread - 2018

brindabella wrote:texl1649 wrote:I wonder if Boeing is contemplating, possibly, a future line where there is one moving assembly line, with NMA, and NSA rolling down sequentially, different models/lengths, but the same basic systems getting installed (but for engines, handled later of course). Shared APU's, cockpits, etc.

Mmm, can't help but be reminded of a certain OEM which has (apparently):- reduced assembly-line staff from 600 or so to maybe 100;

- introduced substantial automation to the same line;

- and nevertheless builds two separate generations of it's airliners on that same line.

EMB and the E1/E2.

And of course integration of that same EMB operation with Boeing is well under way. Funny about that!

Since I haven't seen anyone else suggest this, take a bow!

And to follow this logic along, these skills at EMB would make a strong case not only for parallel assembly-lines in Sao Paulo as well as say Seattle; but also possibly the first developmental MOM/NSA (low-rate) line might be established in Brazil.

cheers

Thx. I do see some great similarities, surely. I also think Boeing has worked for half a century nearly to minimize narrow body weight and model/engine diversity (perhaps the 757 is internally even viewed as a bit of a mistake). The processes will be as fascinating as the soon to come models and offerings, I believe.

-

- Newbiepilot

- Posts: 3646

- Joined:

Re: Boeing 797 Discussion Thread - 2018

I find the freighter market discussion intriguing. That is a discussion that directly affects the business case. There are over 500 757/767 freighters currently in operation. Over 20 years, that represents a sizable market. I think it is very smart studying incorporating the ability to either make a production freighter or enable a potential freighter conversion before they launch. This airplane quite possbily will have the most well vetted business case of any airplane launched and it is good to know freighters are being considered. I think it is a smart move since we have seen Boeing have to relaunch the 737-7 as well as Airbus have to relaunch the A350 and eventually cancel one of the derivatives. Boeing seems like they are on a path to avoid those mistakes.

I seriously doubt they are using this time to rethink cross section like Keesje is implying. There is no evidence supporting that anything he is proposing is being studied or considered. The extra wide narrowbody graphics appear just a distraction in this thread.

I seriously doubt they are using this time to rethink cross section like Keesje is implying. There is no evidence supporting that anything he is proposing is being studied or considered. The extra wide narrowbody graphics appear just a distraction in this thread.

-

- PlanesNTrains

- Posts: 9524

- Joined:

Re: Boeing 797 Discussion Thread - 2018

keesje wrote:PlanesNTrains wrote:keesje wrote:

I don't a new Airbus twin aisle before 2030. Eventually the A330 needs replacement and the A321/322 - A350-900 space needs to be filled. How that will look seems unclear to me this stage. I can google an A370 single aisle on steriod, but lets not post that on the 797 thread.

That’s fine, but the primary question was how would the concept you posted fair up against an A321XLR?

- Superior paylooad range, CASM up to 5000NM/ 280 passengers.

- Dual, direct aisle acces seats for all F/B class passengers

- Wing / engine / LDG / optimized for high capacity / short range with dedicated low MTOW version

- Quicker boarding/ deboarding with 1.5 aisle system, people can pass each other.

- Easier moving around of passengers/ crew service during flight

- Wider seats, bigger windows, bins, lavatories

High NSA/NMA commonality & economies of scale.

I get why it has positives. However, when you get an A321XLR (plus whatever other things they do with the A220/A320 family) at a fraction of the development cost of this combo, and with full commonality in the fleets of scores of airlines, the waters become muddy.

Re: Boeing 797 Discussion Thread - 2018

Conversely, there is going to be a massive shortage of 737/A320 pilots over the next 10-20 years. If Boeing/Embraer envisage a family up to 797 and package it with training (etc.;` services), it could facilitate cargo market share as cargo airlines then won't be competing with Vietjet/India etc. for qualified pilots (and I think the KC-390 future can't be dismissed in this analyses). There are a minuscule number of A32x freighters, though, today, although this could plausibly change. I don't think this is particularly likely to change though, given both the pax demand for the frames.

Re: Boeing 797 Discussion Thread - 2018

I do not think the P2F conversion problem will be given any consideration by Boeing. It seems that new-built freighters are becoming more and more dominant, and I believe Boeing would much rather sell a new freighter than convert an old airliner. Any compromise made to accommodate later conversion will doubtless create less than optimum conditions for its primary use as an airliner. The business has become so competitive that Boeing can not afford that. They will undoubtedly at some point offer a 797F; and I suspect it will have substantial differences to the pax 797, just like the 747F and 777F. And just as the 777 P2F program is unlikely to get off the ground, I do not expect to see a 787 conversion. I expect the 787 will have the same floor loading issue as the 777, and the 797 will as well. Passengers simply do not impose the same unit loads on the floors as does freight, and making the floors strong enough for freight is over design that Boeing can no longer afford. Earlier airliners were in fact overdesigned, but that is a luxury that the airlines no longer want, and hence neither Boeing nor Airbus us going to do it any more.

Re: Boeing 797 Discussion Thread - 2018

I do not think the P2F conversion problem will be given any consideration by Boeing. It seems that new-built freighters are becoming more and more dominant, and I believe Boeing would much rather sell a new freighter than convert an old airliner. Any compromise made to accommodate later conversion will doubtless create less than optimum conditions for its primary use as an airliner. The business has become so competitive that Boeing can not afford that. They will undoubtedly at some point offer a 797F; and I suspect it will have substantial differences to the pax 797, just like the 747F and 777F. And just as the 777 P2F program is unlikely to get off the ground, I do not expect to see a 787 conversion. I expect the 787 will have the same floor loading issue as the 777, and the 797 will as well. Passengers simply do not impose the same unit loads on the floors as does freight, and making the floors strong enough for freight is over design that Boeing can no longer afford. Earlier airliners were in fact overdesigned, but that is a luxury that the airlines no longer want, and hence neither Boeing nor Airbus is going to do it any more.

Re: Boeing 797 Discussion Thread - 2018

keesje wrote:

I don't a new Airbus twin aisle before 2030. Eventually the A330 needs replacement and the A321/322 - A350-900 space needs to be filled. How that will look seems unclear to me this stage. I can google an A370 single aisle on steriod, but lets not post that on the 797 thread.

That's exactly why the 797 is going to be a widebody MoM. If they do NSA first, they're leaving the upper MoM wide open for Airbus to fill it as they like. It's better for Boeing to take advantage of that gap while it's open, which means Airbus' counter will be to rewing and reengine the A320/321/A322, and then Boeing can concentrate 737 sales campaigns where it does best for the next 10 years. After the MoM 797 is well under way and Airbus commits to the larger A320 project, Boeing and Embraer can then work on the NSA family to attack the single aisle market.

-

- Newbiepilot

- Posts: 3646

- Joined:

Re: Boeing 797 Discussion Thread - 2018

SEPilot wrote:I do not think the P2F conversion problem will be given any consideration by Boeing. It seems that new-built freighters are becoming more and more dominant, and I believe Boeing would much rather sell a new freighter than convert an old airliner. Any compromise made to accommodate later conversion will doubtless create less than optimum conditions for its primary use as an airliner. The business has become so competitive that Boeing can not afford that. They will undoubtedly at some point offer a 797F; and I suspect it will have substantial differences to the pax 797, just like the 747F and 777F. And just as the 777 P2F program is unlikely to get off the ground, I do not expect to see a 787 conversion. I expect the 787 will have the same floor loading issue as the 777, and the 797 will as well. Passengers simply do not impose the same unit loads on the floors as does freight, and making the floors strong enough for freight is over design that Boeing can no longer afford. Earlier airliners were in fact overdesigned, but that is a luxury that the airlines no longer want, and hence neither Boeing nor Airbus us going to do it any more.

Boeing is churning 767-300ERs into BCFs. There is huge demand driven by Amazon, DHL, SF Express, UPS, etc. they are also kicking into high gear the 737-800BCF program. We have heard services are going to be part of the business case for the NMA. Freighter Conversions and Landing Gear Exchange programs are some of the highest dollar after market service contracts behind engines.

-

- Newbiepilot

- Posts: 3646

- Joined:

Re: Boeing 797 Discussion Thread - 2018

monomojo wrote:keesje wrote:

I don't a new Airbus twin aisle before 2030. Eventually the A330 needs replacement and the A321/322 - A350-900 space needs to be filled. How that will look seems unclear to me this stage. I can google an A370 single aisle on steriod, but lets not post that on the 797 thread.

That's exactly why the 797 is going to be a widebody MoM. If they do NSA first, they're leaving the upper MoM wide open for Airbus to fill it as they like. It's better for Boeing to take advantage of that gap while it's open, which means Airbus' counter will be to rewing and reengine the A320/321/A322, and then Boeing can concentrate 737 sales campaigns where it does best for the next 10 years. After the MoM 797 is well under way and Airbus commits to the larger A320 project, Boeing and Embraer can then work on the NSA family to attack the single aisle market.

Totally agree. The 737MAX is approaching 5,000 orders and selling well. Some people may see impending doom due to age of the airplane, but the 737 is very competitive with 43% market share vs the A320family. I doubt Boeing has any interest in shelving the NMA, which doesn’t have head to head direct competition in favor of an NSA. I think Keesje is the only person promoting the idea of an extra wide narrowbody

Re: Boeing 797 Discussion Thread - 2018

Newbiepilot wrote:monomojo wrote:keesje wrote:

I don't a new Airbus twin aisle before 2030. Eventually the A330 needs replacement and the A321/322 - A350-900 space needs to be filled. How that will look seems unclear to me this stage. I can google an A370 single aisle on steriod, but lets not post that on the 797 thread.

That's exactly why the 797 is going to be a widebody MoM. If they do NSA first, they're leaving the upper MoM wide open for Airbus to fill it as they like. It's better for Boeing to take advantage of that gap while it's open, which means Airbus' counter will be to rewing and reengine the A320/321/A322, and then Boeing can concentrate 737 sales campaigns where it does best for the next 10 years. After the MoM 797 is well under way and Airbus commits to the larger A320 project, Boeing and Embraer can then work on the NSA family to attack the single aisle market.

Totally agree. The 737MAX is approaching 5,000 orders and selling well. Some people may see impending doom due to age of the airplane, but the 737 is very competitive with 43% market share vs the A320family. I doubt Boeing has any interest in shelving the NMA, which doesn’t have head to head direct competition in favor of an NSA. I think Keesje is the only person promoting the idea of an extra wide narrowbody

The interesting part being that Boeing apparently themselves doesn't have the confidence in launcing the NMA widebody that some members here show. Otherwise they would not delay the launch of the 2-3-2 concept for another 18 months after having talked to all potential customers for years. This is beyond "deliberate". I would consider stop locking myself into the 2-3-2 oval WB at NB cost FataMorgana, maybe take a step back / try rewrite history a bit. Just in case of..

Re: Boeing 797 Discussion Thread - 2018

The basic question is, if the 737 is doing great and the 787 is doing great, why would Boeing launch a plane that sits in between those 2, if they competition has no plane that does.

Re: Boeing 797 Discussion Thread - 2018

seahawk wrote:The basic question is, if the 737 is doing great and the 787 is doing great, why would Boeing launch a plane that sits in between those 2, if they competition has no plane that does.

This is very late to ask this - after years of MOM talk. I have my assumption:

Basically it is all about the successor cycle of the 737- where it is clear that it needs a replacement if a next generation is required. It’s not the 737 itself, but the weakness of the plane very long term. Key: To low over ground- no container capable, very limited (if not none) ‘fly by wire capability’, limited growth potential into the 321 territory and above.

The Mom I believe was always thought to be the first candidate of a series of 737 successor planes – not too far away from the 757/767 ‘2 egg twin’ brothers/ sisters. In the beginning of the MOM talk it was also mentioned : we may have 2 variants/ component sets of some components- basically hinting to this. I could easily follow this strategy and I believe it would be the right one- covering from below the 788 down to the 738 successor. So the MOM origin war rather an NSA-XWB_long range (5000nM) rather than a real MOM

Why does this thought / indication from the earlier stages seem not to be followed anymore? I think it is based on some reasons:

1) The 737MAX success is way better than ever expected – so they will still make ‘easy money’ for a long time – lowering the pressure for replacement early – it may need to come way later than anticipated some years ago.

2) The discussions of the MOM became more a single plane discussion instead of an NSA-XWB-XLR range and the MOM grew larger than originally anticipated- to many different customer needs.

3) the 787 deferred cost haven’t been lowered as needed in order to make room for some years of new deferred cost collection from the first years of a 797 until the other models (NSA 797) could deliver the volume and cost efficiency.

4) The business case built on the single plane became much worse with the sales price eradiation from both the 787 and the A330- leaving less room for good 797 sales price.

5) …

So this is what I believe makes things difficult. Somehow Boeing me need to find back to the original intention of a combined 797 as NSA&MOM built in one factory- efficient but in variants.

Shareholders need to give some time and relax for a few years.

Flyglobal

Re: Boeing 797 Discussion Thread - 2018

I agree with you on the 737 replacement, but with the new cooperation with Embraer, they now have a product line below the 737 and a product line that the Brazilian partners will expect to be kept alive. So a 737 successor would probably grow a bit. Most likely starting at around 180 seats (sardine single class) to ~225 for the standard version and about 260-270 seats for the long version. And with newer engines it will probably squeeze the MoM on all routes that it can handle when it comes to range. So how much range does the NSA need and does it leave enough breathing room between the NSA and the 787(787MLU). Sounds quite expensive to me to have 2 planes so close together.

Re: Boeing 797 Discussion Thread - 2018

The trouble is -they do! It's called the A321NEO.

With the new exit layout and slimline interior it can seat up to 240 pax ( in fact the layout allows for up to 250 pax according to Airbus.

It can be stretched it was proposed by Airbus over 10 years ago but had no takers ( I bet range was a real issue back then - less so now.

There is now an LR version doing 4knm ( and more?) with an XLR to 4.4knm that appears possible with only minor mods'.

The stretch could even be accompanied by a new wing and they have a double bogey MLG if necessary..

So no, if none of this existed or could exist I am sure we would hear nothing about a 'MOM'.But it does or easily could do.

With all this talk of lowest possible price,a metal fuse and proper cargo carrying capacity - and with all the brand new manufacturing technology designed for the 777 ( carbon wing and metal fuse) quite why they have ( from the outset) Ruled Out an aircaft based around the 767 I can't imagine.But. clearly they have and no doubt for good reasons.

With the new exit layout and slimline interior it can seat up to 240 pax ( in fact the layout allows for up to 250 pax according to Airbus.

It can be stretched it was proposed by Airbus over 10 years ago but had no takers ( I bet range was a real issue back then - less so now.

There is now an LR version doing 4knm ( and more?) with an XLR to 4.4knm that appears possible with only minor mods'.

The stretch could even be accompanied by a new wing and they have a double bogey MLG if necessary..

So no, if none of this existed or could exist I am sure we would hear nothing about a 'MOM'.But it does or easily could do.

With all this talk of lowest possible price,a metal fuse and proper cargo carrying capacity - and with all the brand new manufacturing technology designed for the 777 ( carbon wing and metal fuse) quite why they have ( from the outset) Ruled Out an aircaft based around the 767 I can't imagine.But. clearly they have and no doubt for good reasons.

Re: Boeing 797 Discussion Thread - 2018

seahawk wrote:I agree with you on the 737 replacement, but with the new cooperation with Embraer, they now have a product line below the 737 and a product line that the Brazilian partners will expect to be kept alive. So a 737 successor would probably grow a bit. Most likely starting at around 180 seats (sardine single class) to ~225 for the standard version and about 260-270 seats for the long version. And with newer engines it will probably squeeze the MoM on all routes that it can handle when it comes to range. So how much range does the NSA need and does it leave enough breathing room between the NSA and the 787(787MLU). Sounds quite expensive to me to have 2 planes so close together.

What you are describing as teh 737 successor sort of IS the MOM. The likely future especially with the JV with Embraer is for Boeing to develop some kind of MOM that covers the slightly bigger than A321 - slightly smaller than 787-8 capacity slot. Then, using lessons learned and as much commonality as possible, the Boeing/Embraer JV will design and produce a 737 successor that probably covers slightly larger than the 195 E2 on the the low end and something in the 737 MAX 9 capacity on the high end but designed with the small model as the base and a stretch and double stretch that trades range for seating capacity, kind of how the 787 was designed (although the 787-9 ended up with the most range of the 3).

Re: Boeing 797 Discussion Thread - 2018

My (not very educated) guess would be that with the recent Embraer dealings Boeing will "ramp up" NSA development earlier than previously anticipated.

In the US resources are being freed up with the MAX and 781 rounding up, leaving only the 777X in development and Embraer is also pretty much done developing the E2.

Across the two companies they should have enough resources to (somewhat) parallel develop a NSA and MOM, with all benefits that come with such a development proces (i.e. only one system would need to be designed for two aircraft, common materials and parts could be chosen, to a certain extent and pilot/cabin crew training can be kept very close together)

Future would hold a nice balance of E2-NSA-MOM-787-777X

In the US resources are being freed up with the MAX and 781 rounding up, leaving only the 777X in development and Embraer is also pretty much done developing the E2.

Across the two companies they should have enough resources to (somewhat) parallel develop a NSA and MOM, with all benefits that come with such a development proces (i.e. only one system would need to be designed for two aircraft, common materials and parts could be chosen, to a certain extent and pilot/cabin crew training can be kept very close together)

Future would hold a nice balance of E2-NSA-MOM-787-777X

Re: Boeing 797 Discussion Thread - 2018

Newbiepilot wrote:I find the freighter market discussion intriguing. That is a discussion that directly affects the business case. There are over 500 757/767 freighters currently in operation. Over 20 years, that represents a sizable market. I think it is very smart studying incorporating the ability to either make a production freighter or enable a potential freighter conversion before they launch. This airplane quite possbily will have the most well vetted business case of any airplane launched and it is good to know freighters are being considered. I think it is a smart move since we have seen Boeing have to relaunch the 737-7 as well as Airbus have to relaunch the A350 and eventually cancel one of the derivatives. Boeing seems like they are on a path to avoid those mistakes.

I seriously doubt they are using this time to rethink cross section like Keesje is implying. There is no evidence supporting that anything he is proposing is being studied or considered. The extra wide narrowbody graphics appear just a distraction in this thread.

For freighters, there are also A300/310F, and those currently ordered but undelivered 767F might also need to be replaced sometimes down the road too.

As for Keesje's proposal, I guess I would read that as his wishful thinking that "it would be nice if they..."

Who is online

Users browsing this forum: AaronPGH, AECM, airbazar, Airontario, amcnd, AstanaMagic, ATLgaUSA, ausinTex, avianca707359b, Bing [Bot], blockski, BritishB747, Cactusjuba, chicawgo, CriticalPoint, Dominion301, fastmover, Herc4ever, HouTx, jmy007, jplatts, Juju2004, kalvado, latinaviation, LAXdude1023, leftyboarder, Liski, Malayil, MCOTOLONG, melpax, mrsmiley2345, NLINK, PA727, PHLspecial, Puissance, ScottB, seansasLCY, speedygonzales, StarAC17, Tack, TheAccountant, trini81, TropicalSky, UALifer, Weatherwatcher1, WorldFlier and 282 guests